Next Generation Biomanufacturing and Microengineering

This project aims to better understand the lignin-degrading activity of the microbial community harbored by the gut of the lower termite, Reticulitermes flavipes. Termites and their microbial symbionts efficiently and adaptively convert lignin into acetate, and may be considered a model system for sustainable next-generation biomanufacturing. The problem is conventional scale-up of the termite gut microbiome destroys micro-scale chemical gradients, and therefore the microbial community with its distributed functionality is also destroyed.

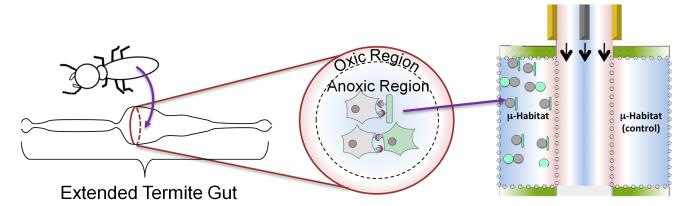

Our approach is to use microfluidic devices to re-capitulate and dynamically regulate the micro-scale condi-tions in the termite gut to support and perhaps modulate the activities of the microbial community (Fig. 1). We aim to control the termite gut microbial community through dynamic external regulation of microscale oxygen supply. In a real termite gut, a diverse and interacting microbial community lives in concentric shells within the termite paunch. The outer-most shell is fully oxygenated; the innermost shell is fully anaerobic.

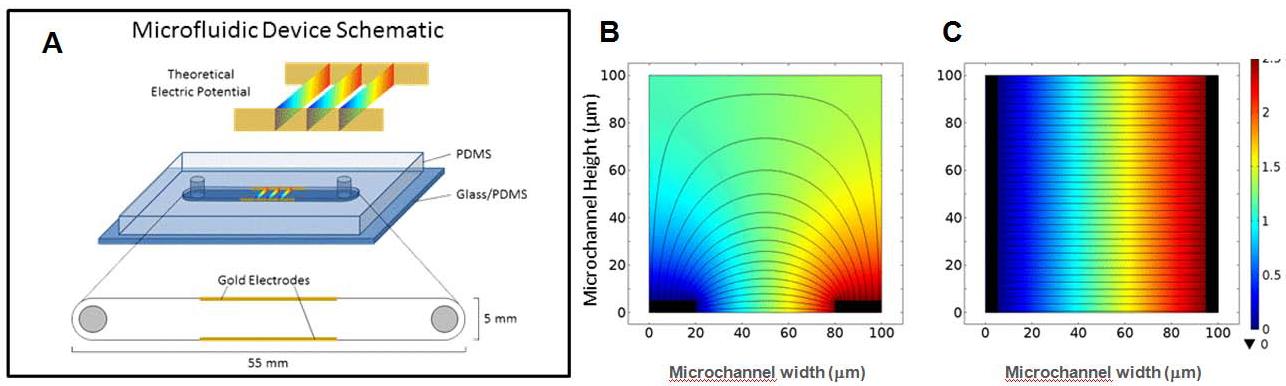

My lab is to developing the microsystems and enabling technologies for the “artificial termite on-a-chip.” This is the central thrust of the $2M project. We are building arrays of growth chambers with in-plane mem-branes supported by posts to contain microbes while providing high transport rates of substrates, products, and electron acceptors. Also, in collaboration with the Mustain lab, we are developing a fast oxygen concentration modulator. We are using electrolysis to create curtains of O2 and H2 along opposite edges of flow channels. The high Péclet number, low Reynolds number flow regime of the microfluidic device enables controlled delivery of O2 and H2 through laminar flow patterning. We have developed a novel chemical syn-thesis technique to bond gold electrodes to the sidewalls only of a closed PDMS device (Fig. 2).1 This technique facilitates uniform potential with depth across the channel.

Fig 2. (A) Schematic of gold sidewall electrodes in a simple PDMS flow cell. Inset shows shape of electrical potential gradi-ent for electrodes bonded along microchannel side walls. In contrast, electrodes are typically placed on the bottom substrate of a flow channel (B). Depending on aspect ratio of channel, such placement results in extreme distortions to the field, and greatly reduces effective potential across the channel compared with sidewall-bonded electrodes (C). (Figure from Kadilak et al.2.)

Additional microfluidic cell culture

technologies devel-oped through this support include implementation of a

fast, non-destructive, spatially-continuous oxygen sens-ing film,2

and development of in-plane membranes to supply microhabitats with a high

diffusive flux while resisting washout from pressure-driven flow.3

We are also working to implement microfluidic sorters to facilitate genetic

analysis of the termite gut microbiome.

Future directions for this work include applying the enabling technologies

to other applications, and working to scale-up our microbial systems

engineering approach. I am currently working with a tissue engineering

expert on an NIH R01 proposal that will employ our dynamic oxygen gradient

generator to study cardiac infarction. Also, I am working with other members

of the EFRI team on an adaptive biomanufacture proposal targeting DOE.

People Involved: Andrea Kadilak, Jinzi Deng, Ying Liu

Collaborators: Dr. Bill Mustain

Funding: NSF EFRI, NSF GK-12

References:

1. Kadilak, A. L., Shrestha, S., Bernard, J. R., Mustain, W. E. & Shor, L. M. Selective Photopatterning of Chemically-bonded Gold Electrodes on PDMS Microchannel Side Walls In review (2013).

2. Deng, J., Dhummakupt, A., Samson, P. C., Wikswo, J. P. & Shor, L. M. Dynamic dosing assay relating real-time respiration responses of Staphylococcus aureus biofilms to changing microchemical conditions. Analytical Chemistry 85, 5411-5419, doi:dx.doi.org/10.1021/ac303711m | Anal. Chem. 2013, 85, 5411−5419 (2013).

3. Kadilak, A. L., Furrer-Chau, J. & Shor, L. M. Hydrogel-filled capillaries for nutrient delivery and flow control in microfluidic cell culture. In preparation (2013).